3D printing (FDM)

Fused Deposition Modeling (FDM) is a commonly used 3D printing technique that uses polymer monofilament as its ‘ink’. This monofilament is made through continuous extrusion of polymer pellets.

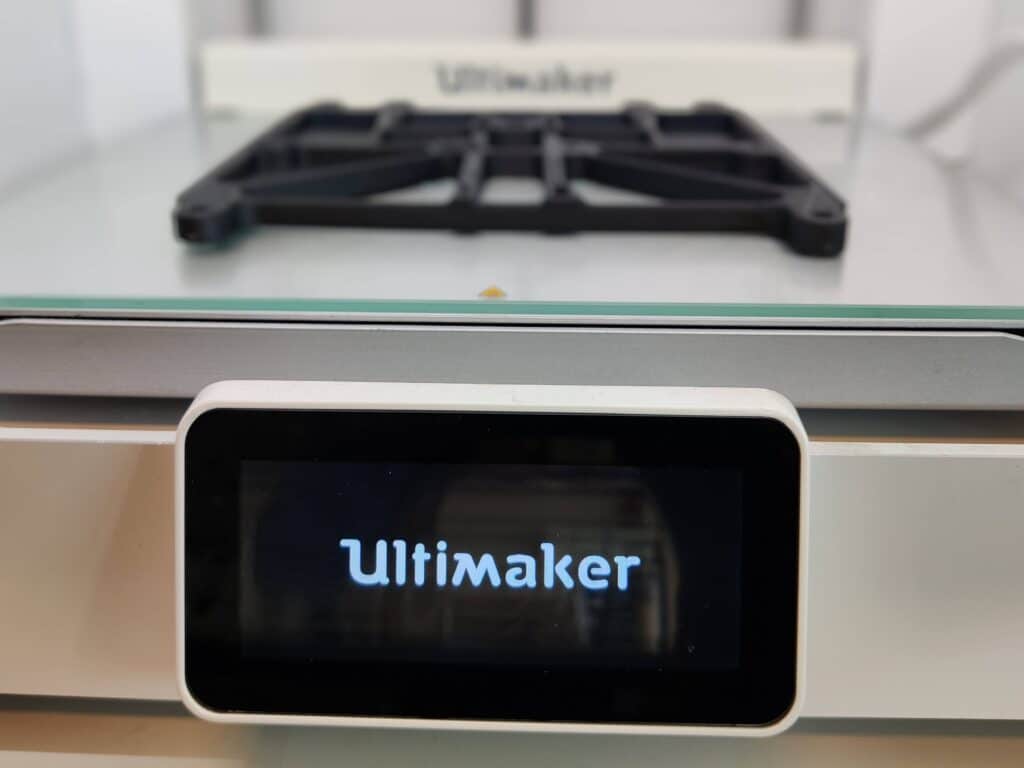

Senbis is fully capable of both producing this monofilament as well as 3D printing the resulting filaments in order to test its properties. This is all done in house and uses as little as a few kilograms of material. We can test the printability and physical properties of a new experimental material as well as find the right material for your application. If needed, special prints and tests can be developed to fit your needs.

Often, production of monofilament and subsequent printing is combined with mechanical tests like tensile, flexural and impact tests. Thermal analyses like MFI/MVR and DSC can also be performed on the filament. We can produce both commonly used filament dimensions: 1.75 mm and 2.85 mm. The following printers are available to your disposal:

- Ultimaker S5 (2.85 mm)

- Ultimaker 3 (2.85 mm)

- Prusa i3 MK3 (1.75 mm)

- Felix Pro3 (1.75 mm)