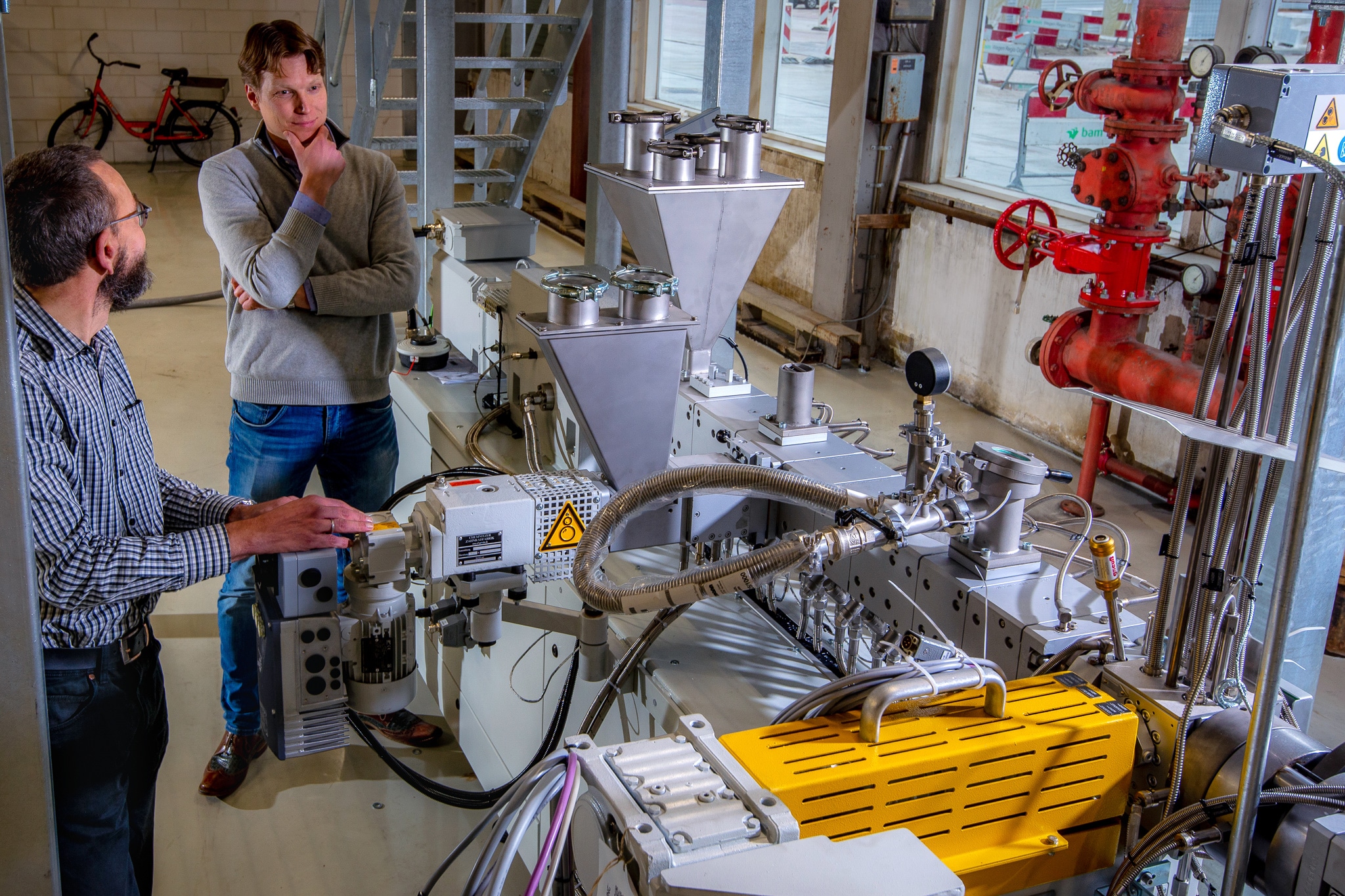

Twin screw extruder pilot (KraussMaffei 28)

Senbis Group invested through its subsidiary SPIC Facilities B.V. in a fully equipped new twin screw extruder, the KraussMaffei ZE28 BluePower. This machine is operational since Q1 2022. The twin screw extruder can be used to produce compounds of (bio)polymers in combination with additives (liquid, powder or granulates). We can also use this twin screw extruder […]

Twin screw extruder pilot (ZSK 30)

This extruder is ideal for compounding polymers, copolymers and additives. The Werner Pfleiderer, Type ZSK 30 is a co-rotating 30 mm twin screw extruder. The extruder is electrical heated (5 zones) and equipped with a K’tron 20 and K’tron 35 dosing unit. The throughput can be up to 10 kg/hour and is ideal for compounding […]

Haake Polylab Kneader

Haake Polylab Kneader explained Instead of an extruder module, a kneader can be equipped on de base module. This is a system with two parallel rods optimized for compounding. Several polymers and additives can be compounded on a small scale (appr. 70g per batch) to provide material for analyses such as DSC, RDS and density. […]

Haake Polylab Filmcasting

Haake Polylab Filmcasting explained When a slit die (8 cm) is installed on the extruder module new possibilities arise. In combination with a roller system which is temperature controlled (-30°C to 200°C) films of many different thermoplastics can be made. By adjusting the drawing speeds and extruder RPM, the width and thickness is controlable.

Haake Polylab Filmblowing

Haake Polylab Filmblowing explained When our Haake Polylab system is equipped with the film blowing module, Polymers can be tested for their ability to form a film. The circular slit die, air inlet and cooling ring allow for an accurately controlled blowing process. We recommend this service to be combined with TNF measurements, as for […]

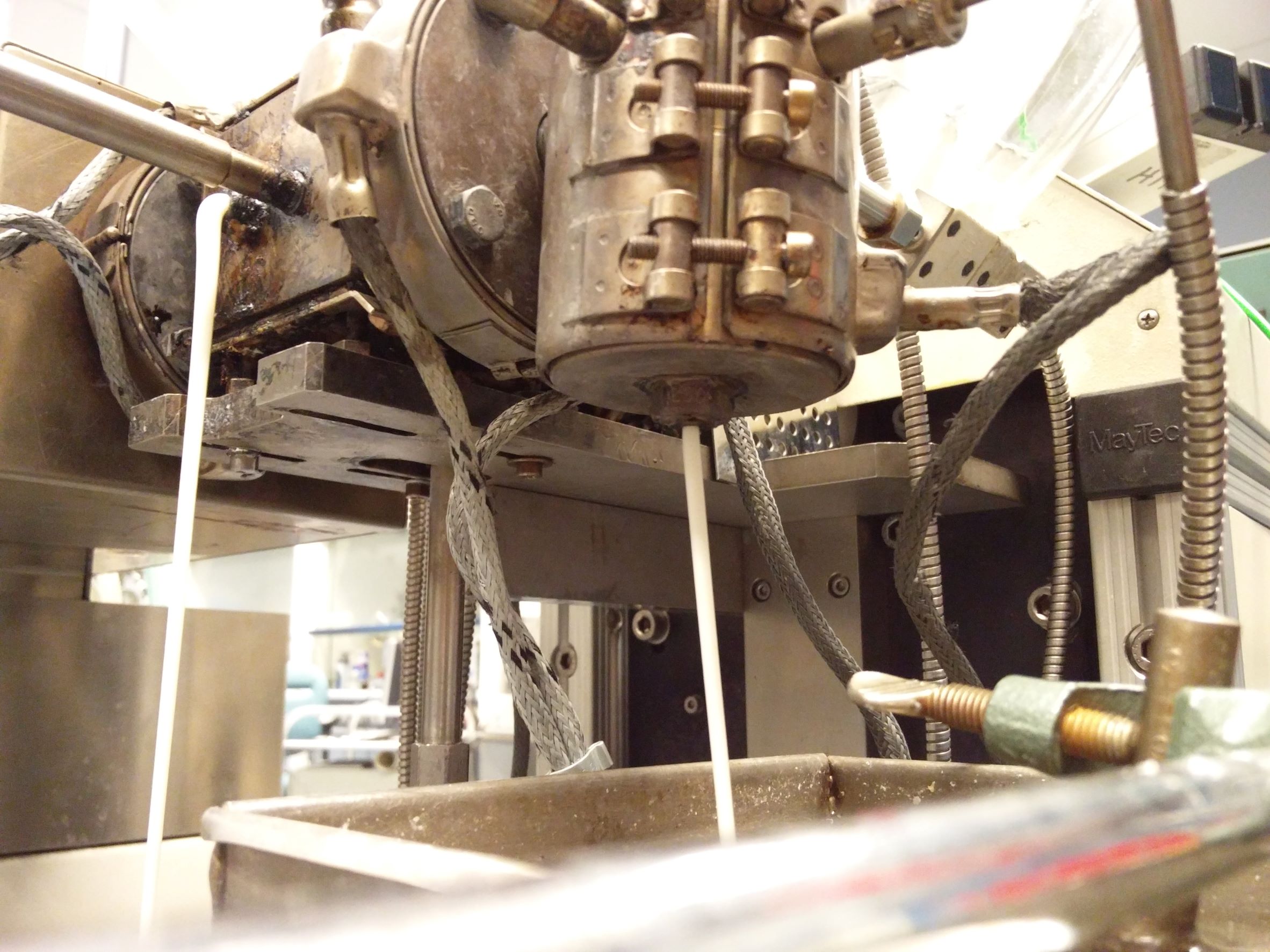

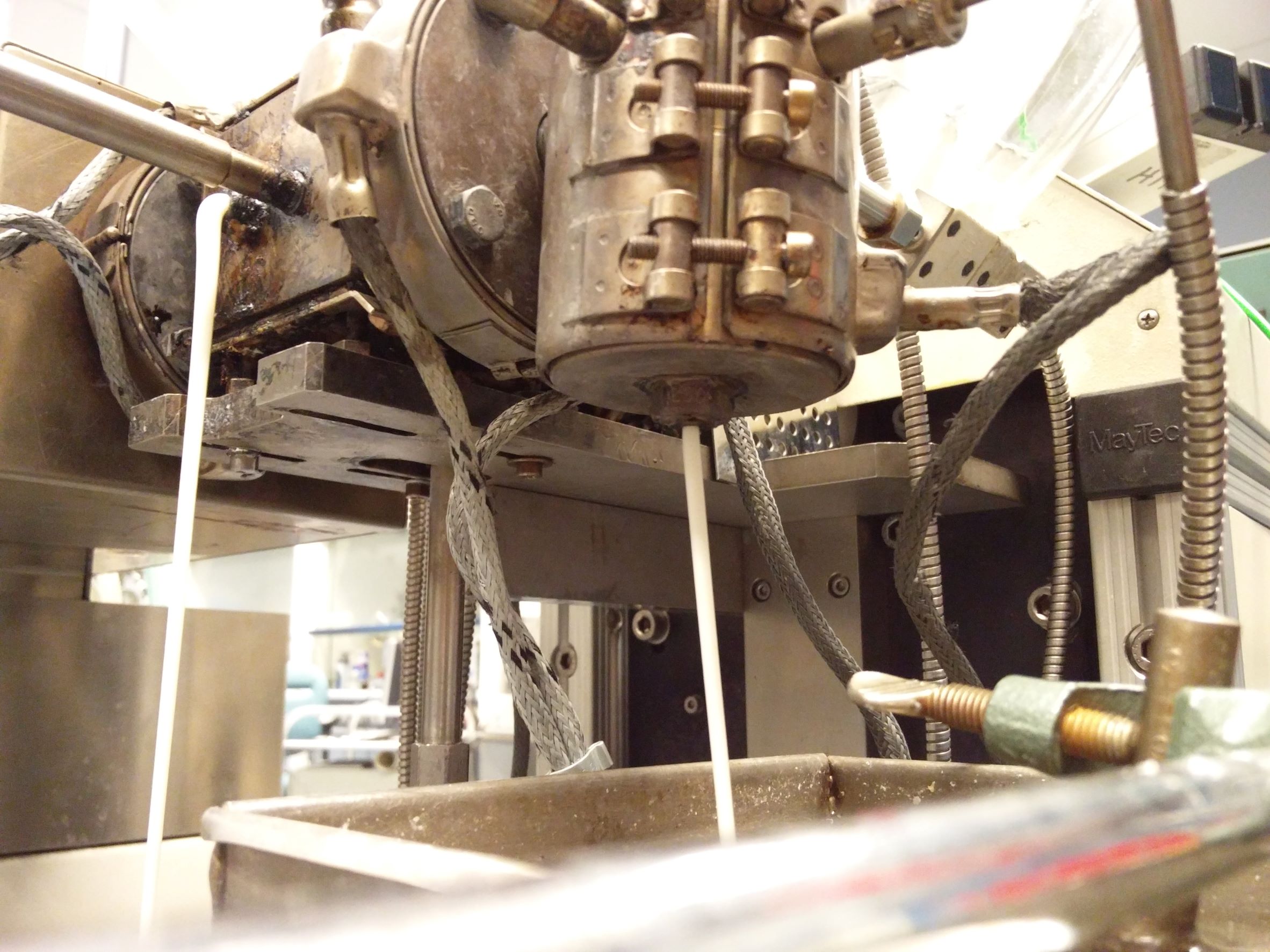

Haake Polylab Filament Extruder

Haake Polylab Filament Extruder explained The Haake polylab system is a versatile piece of laboratory equipment. Its base consists of a powerfull motor and a torque measurement device. On this base unit an extruder module can be attached. This module is equipped with a Fasti resin drying to ensure that the extrudable polymer stays dry […]

Haake Polylab Kneader

Haake Polylab Kneader explained Instead of an extruder module, a kneader can be equipped on de base module. This is a system with two parallel rods optimized for compounding. Several polymers and additives can be compounded on a small scale (appr. 70g per batch) to provide material for analyses such as DSC, RDS and density. […]

Haake Polylab Filmblowing

Haake Polylab Filmblowing explained When our Haake Polylab system is equipped with the film blowing module, polymers can be tested for their ability to form a film. The circular slit die, air inlet and cooling ring allow for an accurately controlled blowing process. We recommend this service to be combined with TNF measurements, as for […]

Haake Polylab Filmcasting

Haake Polylab Filmcasting explained When a slit die (8 cm) is installed on the extruder module new possibilities arise. In combination with a roller system which is temperature controlled (-30°C to 200°C) films of many different thermoplastics can be made. By adjusting the drawing speeds and extruder RPM, the width and thickness is controlable.

Haake Polylab Filament Extruder

Haake Polylab Filament Extruder explained The Haake polylab system is a versatile piece of laboratory equipment. Its base consists of a powerfull motor and a torque measurement device. On this base unit an extruder module can be attached. This module is equipped with a Fasti resin drying to ensure that the extrudable polymer stays dry […]